5 Best EMC Books to read in 2023 (Recommended by EMC Experts)

The EMC world has grown quite fast in the past few years. Technology and standards are continuously evolving and becoming more complex to fit our...

In any product development process, the initial step is to validate the device's performance and functionality. For electronic devices, a crucial part of this validation process is to ensure they meet Electromagnetic Compatibility (EMC) compliance standards. These compliance tests are typically conducted in a certified in-house testing facility. Passing EMC/EMI tests signifies that your device's electromagnetic emissions are within acceptable limits and adhere to the relevant regulatory standards.

EMI, which stands for Electromagnetic Interference, is a subset of Electromagnetic Compatibility (EMC). When conducting pre-compliance tests, the primary focus is on evaluating and addressing EMI, which refers to the actual electromagnetic disturbances or emissions originating from the device.

Every electronic product, whether it's a laptop or a smartphone, must successfully pass compliance tests at an accredited testing facility. Failing to meet these mandatory federal compliance standards prohibits the sale of the product.

The final phase of compliance testing can be quite costly. If a product fails these tests, it necessitates redesign efforts, impacting the product development timeline. Such delays not only increase production costs but also delay the product's entry into the market.

Pre-compliance EMC testing is a proactive approach to identifying and rectifying potential EMC issues during the design stage of a product. It involves conducting EMC tests before the formal test-house certification to ensure that the product meets the necessary EMC standards. This process helps in reducing the risk of product failure and the associated costs of re-testing and redesign.

The high EMC test failure rate can be attributed to several factors:

EMC compliance necessitates a profound understanding of electromagnetic principles and their application in electronic product design. This expertise is often lacking, especially in small and medium-sized enterprises (SMEs) with limited resources.

Even when these principles are understood, implementing them correctly during the design phase can be daunting, particularly for complex products with multiple interacting components.

The regulatory landscape for EMC is intricate and constantly evolving. Applying the wrong regulations can lead to non-compliance.

Despite the best design practices, unforeseen interactions among circuit elements can result in EMC failures.

The inclusion of non-compliant modules or subassemblies in the design can jeopardize the final product's EMC compliance.

The consequences of EMC test failure are severe, including high re-testing costs, project schedule delays, and postponed market introduction. For an engineer in an SME, sending a new product for compliance testing often feels like a shot in the dark.

Pre-compliance testing is a proactive approach that involves testing electronic devices for EMC issues during the design and development phase, well before official compliance testing is required. Pre-compliance tools are the key to success in this endeavor for several reasons:

Enhances Project Agility: Time is always of the essence, especially when gearing up for a product launch. The last thing you want is to reach the launch date only to discover that your product falls short of EMC standards. Such setbacks can result in substantial delays, disrupt your entire schedule, and lead to financial uncertainties. Ensuring compliance from the outset keeps you prepared.

Reduces Risk of Failure and Ensures Compliance: While EMC compliance offers no guarantees, beginning with a compliant product significantly enhances your chances of success, instilling confidence in your compliance efforts.

Reduces Future Warranty Issues: Providing a limited warranty is standard practice for product offerings. This not only strengthens your brand and reputation but also fosters customer trust and loyalty. More importantly, in case issues arise, you'll have a better grasp of the root causes, which is crucial for effective product rectification or replacement. Electromagnetic interference can have a detrimental impact on products, making EMC compliance, both pre- and post-testing, a vital component in minimizing warranty issues.

Lowers Testing and Design Costs: One of the foremost advantages of pre-compliance testing is cost reduction. Multiple testing phases can quickly escalate expenses. If a non-compliant device undergoes testing and fails, it may increase respins in pcb design or delays in final product prototype to meet EMC standards. By solving EMC challenges at pcb design level significantly lowering overall costs.

Mitigates Over and Under Design Challenges: Overdesign and over-engineering, as well as under-design and under-engineering, represent the two extremes in the design and development spectrum. Overdesign results from a lack of full understanding of EMC standards and guidelines, leading to unnecessary work and increased manufacturing costs. Conversely, under-design or under-engineering entails additional costs due to repetitive reengineering and retesting. Pre-compliance testing effectively eliminates both issues by ensuring products are developed in a balanced and cost-effective manner.

Solving EMC/EMI early at the design phase: Detecting EMC errors in the early stages of design stage provides the advantage of addressing potential issues promptly. Instead of sending a product for testing, waiting for results, and potentially returning to the design phase, staying within the design and development phase until you're certain the product functions, complies with regulations, and meets customer expectations is the more efficient approach.

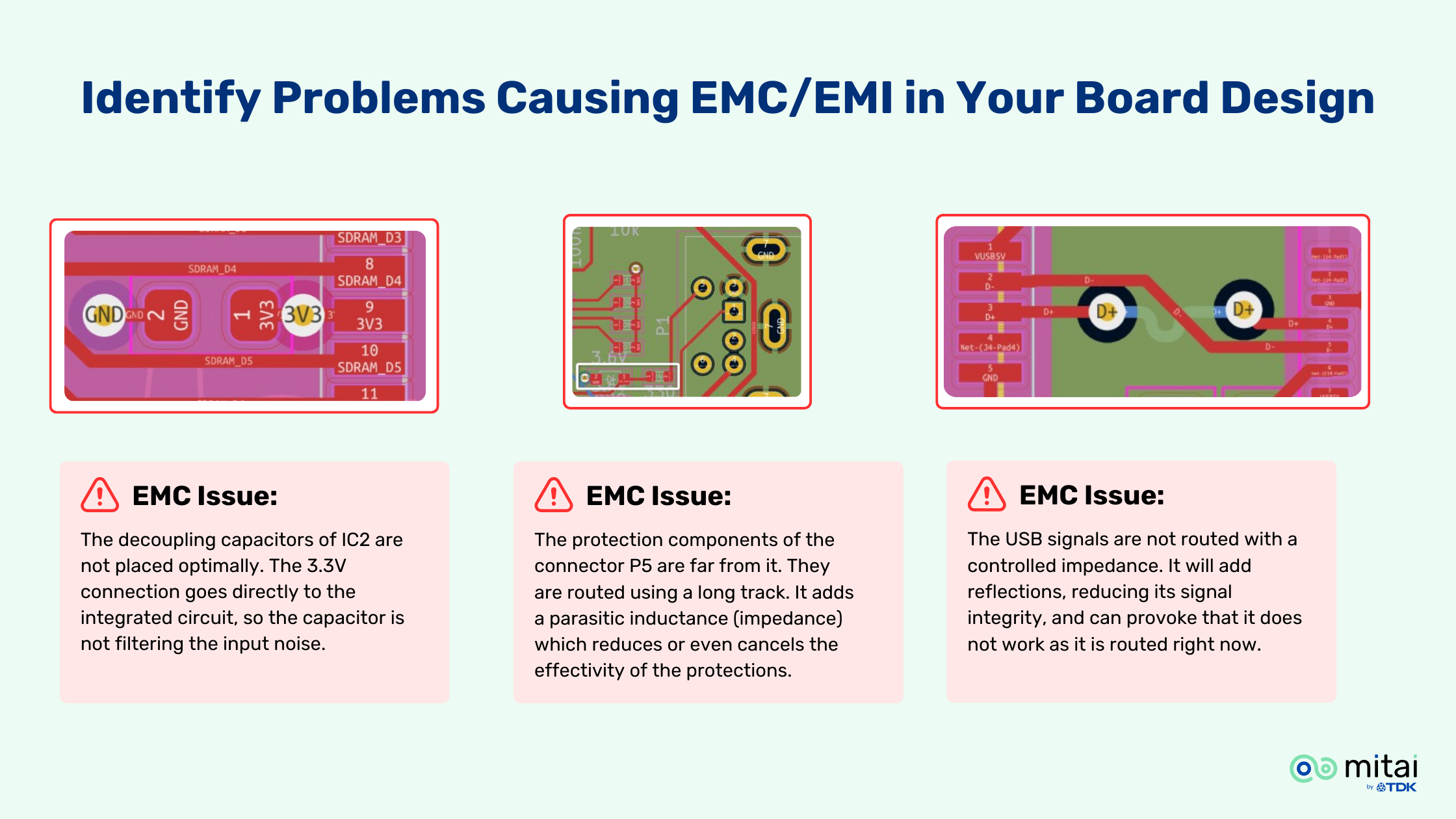

Mitai, an augmented AI-powered pre-compliance tool, aims to solve EMC challenges for small and medium-size companies. It offers a user-friendly interface that analyses your PCB designs for potential EMC problems and provides an overview of the detected top EMC/EMI issues in your board design. Mitai then offers recommendations and explanations to optimise your PCB design for passing EMC test first time right.

Precise EMC Issue Identification: : Mitai's ability to precisely identify EMC issues is invaluable. It empowers design engineers to catch potential problems early in the design phase, reducing the risk of costly compliance failures during official testing and certification. This early detection ensures a smoother compliance journey, saving time and resources.

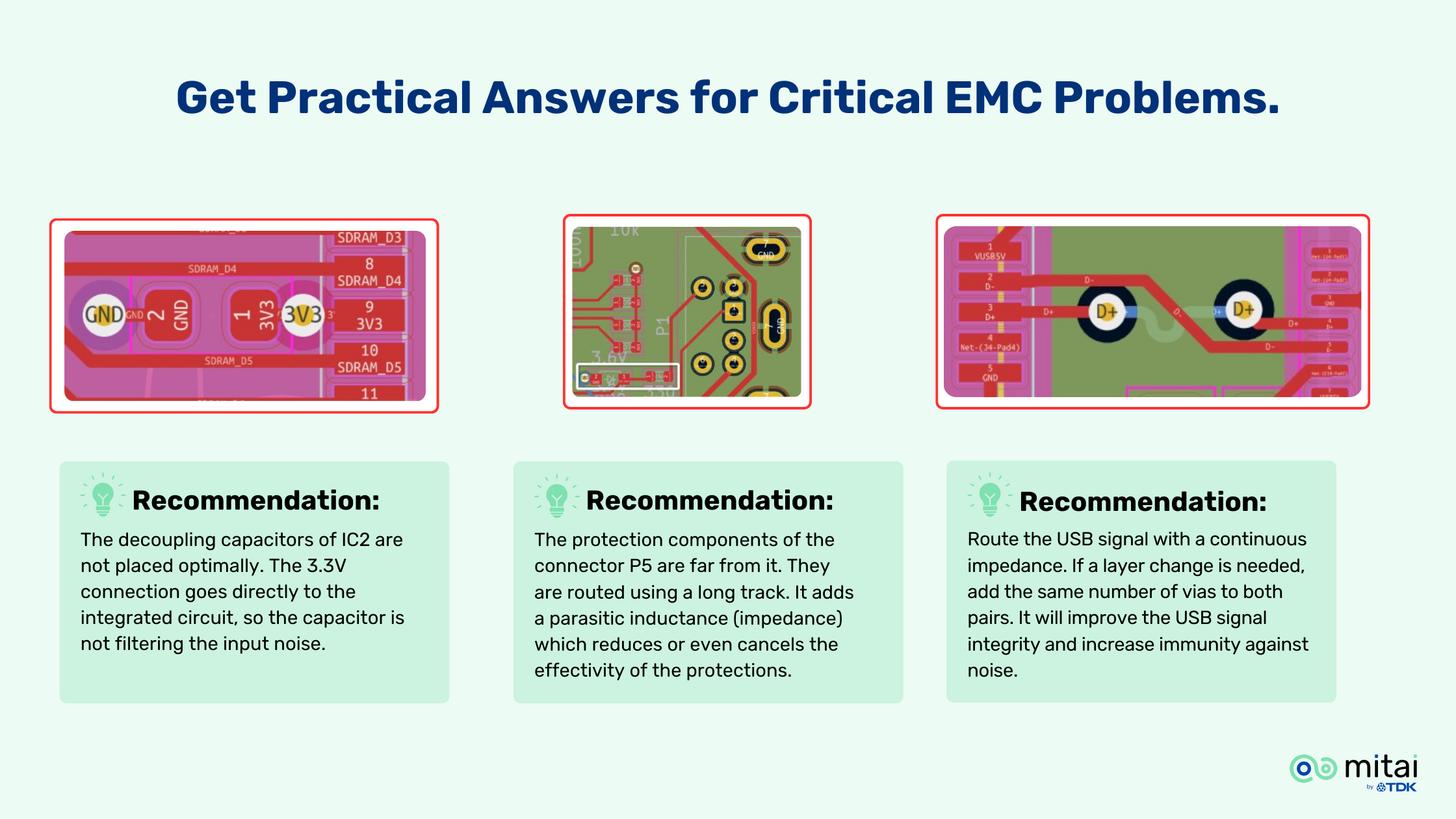

Practical Recommendations: Design engineers benefit from Mitai's practical recommendations, tailored to address critical EMC issues. Using Mitai in the pre-compliance stage enables engineers to proactively resolve these problems, preventing expensive project overruns and delays during official testing. Mitai's recommendations provide a clear roadmap to EMC compliance, enhancing efficiency and reducing compliance-related stress.

Accept PCB Design format from all major tools: Mitai primary format is ODB++, providing comprehensive PCB design and manufacturing data. Additionally, Mitai accepts KiCad_pcb for KiCad software use, .brd for Cadence Allegro users, and .PcbDoc for Altium Designer.

Unlimited Uploads & Analysis: During the pre-compliance stage, design engineers often conduct multiple iterations of their designs to achieve EMC compliance. Mitai's offer of unlimited uploads and analysis without extra charges ensures that engineers can make continuous improvements. This freedom to iterate and analyze multiple designs allows design engineers to fine-tune their projects thoroughly before official testing, enhancing their chances of success.

PCB Health Score: The PCB Health Score provided by Mitai is a valuable asset in pre-compliance efforts. Design engineers gain a comprehensive overview of their PCB design's quality, helping them make informed decisions during the design phase. This assessment supports engineers in achieving EMC compliance right from the start, reducing the need for costly redesigns and retesting.

Personal EMC Expert Consultations: Mitai's provision of personal EMC expert consultations during the pre-compliance phase is a significant advantage. Design engineers can benefit from expert guidance and insights, ensuring that their designs align with EMC standards early on. This guidance is essential in preventing compliance issues and provides design engineers with the support they need to navigate the complexities of EMC compliance effectively.

As an EMC-Compliance-Focused Design Engineer, your journey towards EMC excellence begins with Mitai. Our cutting-edge augmented AI tool empowers you to achieve EMC compliance on the first prototype, eliminating the costly and time-consuming process of redesigning your board. Mitai goes beyond detection; it offers actionable recommendations to address EMC problems effectively. Say goodbye to project overruns and delays by following our expert guidance. Continuous improvement is at your fingertips—upload your designs as often as needed. No need for expensive tools or extensive training; just upload your data and let Mitai work its magic. And, for those moments when you need expert advice, our network of EMC professionals is just two clicks away, ready to provide recommendations and tips to alleviate your EMC headaches.

Achieving EMC compliance is a formidable challenge, especially for SMEs. However, tools like Mitai make it not only achievable but efficient. By identifying and resolving EMC problems at the design level, Mitai helps SMEs save time, money, and resources, ensuring a smooth and successful product launch. By equipping yourself with a sound understanding of EMC principles and harnessing the power of augmented AI, you can transform the intimidating prospect of EMC compliance into a well-aimed arrow, hitting the bullseye of EMC excellence.

The EMC world has grown quite fast in the past few years. Technology and standards are continuously evolving and becoming more complex to fit our...

In the realm of electronic device testing, ensuring the accuracy and...

Prevent product design setbacks and start saving money.

Subscribe to stay updated on Mitai news, articles and resources.

Mitai by TDK

© 2023

All rights reserved.